THE PROCESSING OF FLAX

Throughout the history of Doukhobor life, self sufficiency has been a hallmark, not the least of which was the creation of materials for clothing, bedding, household use such curtains, towels, and decorative runners.

This included everything from a man’s hemp or linen Sunday suit to a gaily coloured silk type or linen ‘costume’ for ladies and children.

Throughout the history of Doukhobor life, self sufficiency has been a hallmark, not the least of which was the creation of materials for clothing, bedding, household use such curtains, towels, and decorative runners.

This included everything from a man’s hemp or linen Sunday suit to a gaily coloured silk type or linen ‘costume’ for ladies and children.

The industrious toilers made all as a matter of course, and the fabrication factors for hemp, flax and wool followed a general overlapping.

When wool was available, some arduous steps were skipped - this article will deal with the root [literally] methods in those cases where there was no wool, and the fibres were grown and processed similarly; first of all hemp, and in this case, the cultivation of flax. Growing flax for fiber to spin into linen requires many steps.

Flax and hemp had a bonus quotient, as the seeds were used in cooking, and the oil that was rendered had multi-uses from cooking and even paint thinner, used to season ladle carvings in final stages and other industrial uses. Also the health benefits of hemp and flax seeds and oil are well known, and no doubt helped the hardy workers maintain their rugged good health.

When wool was available, some arduous steps were skipped - this article will deal with the root [literally] methods in those cases where there was no wool, and the fibres were grown and processed similarly; first of all hemp, and in this case, the cultivation of flax. Growing flax for fiber to spin into linen requires many steps.

Flax and hemp had a bonus quotient, as the seeds were used in cooking, and the oil that was rendered had multi-uses from cooking and even paint thinner, used to season ladle carvings in final stages and other industrial uses. Also the health benefits of hemp and flax seeds and oil are well known, and no doubt helped the hardy workers maintain their rugged good health.

THE PROCESS

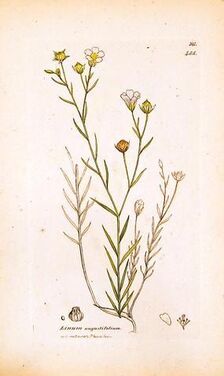

Seed is sown in early spring. This sowing must be done very early in the morning on a windless day due to the very small size of the seed. Flax linen grows in fertile well-drained soil. The flax blossoms in mid-summer.

When ripened the plants are pulled and cured in the sun on a hemp or cotton sheet or laid out on a suitable meadow. In other cases they were stooked, bundles tied together standing in the fields until dehydrated.

The seeds are beaten out with a flail or club like sticks, similar to separating sunflower seeds. Some seeds are stored for next year’s sowing, while the rest are taken to the community plant where they are roasted and pressed to produce oil for table and cooking purposes.

Once it is harvested and the seeds removed, it needs to be retted. This is a long process of weakening the hardy stalks. The flax stems are immersed in water at a local pond or river for 10 to 20 days, which softens the fibres. Often this was supervised by children preventing stalks from floating away and so they were submerged in the water, not just floating on top. Many seniors can tell you about this duty as well as washing wool in the streams, some staying below to catch run away strands. This is the retting stage.

Once it is harvested and the seeds removed, it needs to be retted. This is a long process of weakening the hardy stalks. The flax stems are immersed in water at a local pond or river for 10 to 20 days, which softens the fibres. Often this was supervised by children preventing stalks from floating away and so they were submerged in the water, not just floating on top. Many seniors can tell you about this duty as well as washing wool in the streams, some staying below to catch run away strands. This is the retting stage.

The stalks are taken out of the water and dried in the sun and then broken on a swingle board, a long wooden knife inserted between two boards for the initial breaking down. Retting flax is the process of freeing the flax fibres from between the inner core and the outer layer of the flax stalks.

The fibre you want to work with extends from the top of the plant into the root in long strands between these two layers. Separating them requires that you dissolve the pectin that holds everything together and you do that with water. There are microorganisms involved, but your part is only to place the stalks in water and the microorganisms do the work. This is the initial breaking down of the sturdy stalks.

The stalks are taken out of the water and dried in the sun and then broken on a swingle board, a long wooden knife inserted between two boards for the initial breaking down. Retting flax is the process of freeing the flax fibres from between the inner core and the outer layer of the flax stalks.

The fibre you want to work with extends from the top of the plant into the root in long strands between these two layers. Separating them requires that you dissolve the pectin that holds everything together and you do that with water. There are microorganisms involved, but your part is only to place the stalks in water and the microorganisms do the work. This is the initial breaking down of the sturdy stalks.

Then the stems are pounded in a wooden mortar with beetles [mallets] a heavy hand tool, usually made of wood, used for ramming, pounding, or beating. Called rippling or scutching, this a major process of making the fibres pliable and often two or more ladies would take turns smashing their mallets at the stalks placed in the hollowed out stumps.

A bundle amount of flax is put on a toothed wooden board, a hatchel and the courser parts are combed out by a wooden hand comb, while slightly moistened. What is left on the hatchel is fine silky fibres ready to be spun. This is the final breaking down of the stalks into the fine fibres. Once they are spun into threads, they are ready for the loom where they will be woven into linen.